La mejor alternativa en bombas industriales

Bombas ANSI con la máxima cobertura hidráulica al ofrecer impulsores abiertos y cerrados

Bombas con carcasa BIPARTIDA, con un diseño robusto para las aplicaciones más severas

Bombas verticales tipo turbina, verticales tipo turbina enlatada, doble voluta y tipo sumidero

Bombas API-610 11ª Ed. WORTH-LINE®

Estamos remodelando nuestra página para ti

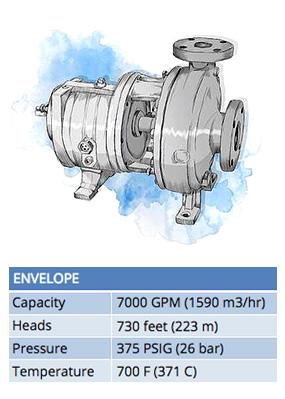

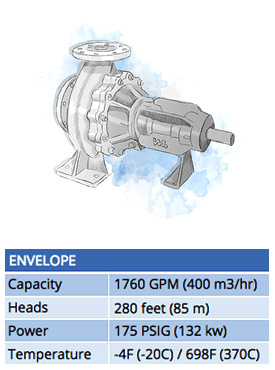

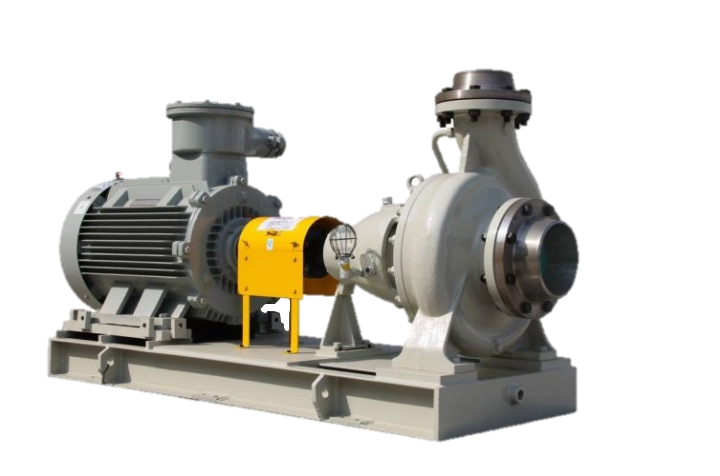

8196 SERIES

WorthLine Series 8196 centrifugal chemical process pumps are designed to insure long continuos service life at low cost.

These pump Series provides the ultimate in standarization of process pumps. With wide parts interchangeability among pump sizes, fewer parts are required for inventory.

MAIN APPLICATIONS

• Chemical processing.

• Pollution control.

• Food & Beverage process.

• Primary metals treating.

• General petrochemical applications.

• Pulp and paper liquors and coatings.

MAIN FEATURES

• Back-pull-out design.

• Simple and fast external impeller adjustment.

• Maximum sealing flexibility.

• Heavy-duty shaft with renewable sleeve.

• Satandard labyrinth oil seals.

• Heavy walled casing with drain.

• Wide variety of metallurgies available.

MAIN BENEFITS

• Maximum interchangeability gives minimum spare parts inventory.

• Low operation and maintenance costs.

• Superior resistance to pipe loads.

• Best design for handling corrosives, erosives and stringy material.

• Longer life for critical parts such as shaft, bearings and seals.

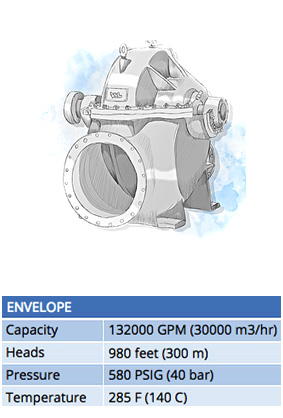

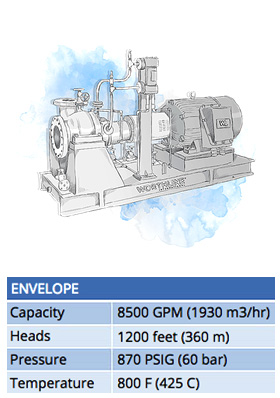

L, N, NH, LR SERIES

Split Case Series are axially spli, double suction pumps design featuring an extense impeller and volute combinations resulting in quite operation, los NPSH requirements, and high efficiency operation in all applications.

These pumps are ideally suited to handling raw water, clean water, service water and seawater. They transport fluids with a minimum of flow resistance, thus lowering the energy and life cycle costs of the systems they are installed in.

MAIN APPLICATIONS

• Extraction, pressure boosting and general transport in water utilities and desalination plants.

• Cooling and service water supply in power stations and industrial plants.

• Fire-fighting systems.

• Sewage collection and treatment.

• General petrochemical applications.

• Groundwater development and irrigation.

MAIN FEATURES

• Double suction impeller and heavy-duty double volute casing.

• Hydraulically balanced impellers.

• Independent cast seal chambers.

• Shaft designed to minimize deflection.

• Corrosion and abresion resistant materials for shaft protecting sleeves, casing and impeller wear rings, and impeller.

• Horizontal or vertical installation.

• Choice of bearings and configurations.

• Comprehensive range of accessories.

MAIN BENEFITS

• Optimum axial and radial thrust balance over the full operating range.

• Robust bearings and a rigid shaft ensure smooth operation with low vibration levels and a long service life of bearings, shaft and shaft seals.

• Low NPSH requirements ensures smooth, efficient operation on all conditions.

• Reduced maintenance costs caused by wear.

• Maintenance friendly design enables fast maintenance and ensures short downtimes.

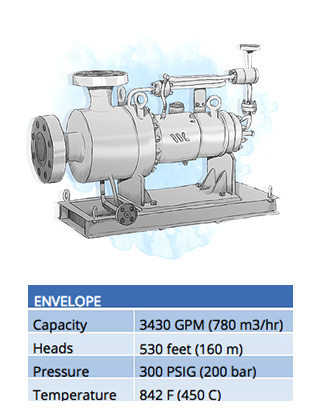

CMP SERIES

Used for aggressive, inflammable, explosive, toxic or valuable liquids and liquified gases; when leakage is not an option. Canned Motor Pumps are a combination of centrifugal pumps with a 3-phase induction motors. The impeller and rotor are installed on a single shaft. The stator liner, or so called "can", separates the stator chamber from the wet rotor chamber.

The design is without a shaft seal and therefore free of leakage. The pumping liquid cools and lubricates the slide bearings and the rotor chamber. The secondary pressure containment, which is achived by the stator shell, provides the safety level for personnel and the environment.

MAIN APPLICATIONS

• Hazardous Chemicals.

• Petrochemical - oil refining.

• Liquified Gases.

• Reverse osmosis.

• Utilities: air conditioning and boiler circulation.

• High melting temperature liquids.

MAIN FEATURES

• Leakproff design.

• Airtight and compact design.

• No dynamic shaft seals.

• Explosion Proof.

• Quiet operation. Low noise and low vibration.

• High weather and dust resistance.

• No external lubrication needed.

• Design flexibility according to the application requirements: self-priming, slurries, high temperature, high pressure, reverse circulation, etc.

MAIN BENEFITS

• Integrated pump and motor ensures environmental protection and on-site safety.

• Low life cycle cost.

• Reduced installation costs; alignement of motor and pump is not necessary.

• Compact integrated design, less space required.

• Easy of maintenance. Field repairable.

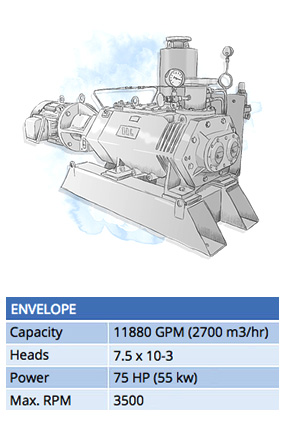

DVP SERIES

The hybrid screw design with engineered combination of variable pitches, in comparison with traditional ones, significantly increases compression efficiency for faster and smoother pumping, decreasing heat generation for safe pumping, decreasing heat generation for safe pumping, which comes from the specialty design of unique hydronynamic spiral jacket cooling mechanism.

MAIN APPLICATIONS

• Solvent recovery.

• Evaporation.

• Crystallization.

• Distillation and Filtration.

• Coating / Impregnation.

• Drying / Freeze Drying.

• Degassing.

• Extrussion / Die Cast.

• Sterilization.

MAIN FEATURES

• Oil and water FREE operation.

• High volume efficiency screw type rotors.

• No metal-to-metal contact between rotors and casing.

• Variable pitch screws.

• Fast pumping down.

• Unique hydrodynamic spiral jacket cooling.

• Complete range of accessories.

MAIN BENEFITS

• Low noise level and vibration.

• Low discharge temperature.

• Low power consumption.

• Lower maintenance costs.

• Superior stand-alone ultimate vacuum.

HTT SERIES

WorthLine's heat transfer pumps are designed for the transport and recirculation of heated mineral oils and/or oils of a synthetic basis. These pumps are single stage volute type with horizontal axial inlet and vertical radial discharge, for the safe transfer of oils up to 350ºC, without the necessity for external cooling of the pump.

MAIN APPLICATIONS

• Paint and dye manufacturing.

• Heating tank mixing and recirculation.

• Glass manufacturing.

• Heat transfer and exchange applications.

• Leather and rubber industries.

• Boiler feed.

• Baking and frying.

• Steel manufacturing.

MAIN FEATURES

• Back-pull-out design.

• Close type hydraulically balanced impeller.

• Drain connection.

• Volute casing with cast-on feet.

• Casing cover with throttling/cooling stretch and bearing bracket.

• Bearing bracket with support foot.

MAIN BENEFITS

• Easy, fast and uncooled maintenance.

• Dry installation.

• Maintenance free mechanical seal.

PWL SERIES

As per the engineering and safety parameters of ISO13709/API 610 standards, the WORTHLINE's PWL pump provides maximum mechanical and hydraulic design flexibility. With customization for individual applications, this pump is available in a variety of optional configurations.

The PWL is the pump of choice for severe chemical, petrochemical, refining and heavy-duty industrial service when reliable performance is required. This pump Series provides users with the important mechanical, hydraulic, emissions control and safety components required by the latest ISO-13709 / API-610 standards.

MAIN APPLICATIONS

• Waste processing.

• Caustic and Chlor-alkali.

• Acid transfer.

• Volatile organic compounds.

• Polymers.

• Slurry processing.

• Distillation.

MAIN FEATURES

• Centerline supported pump casing.

• Dynamically ballanced precision cast impeller.

• Flanges in accordance with ANSI B16.5 Class 300 RF standard or 600 RF as optional.

• ISO-21049 / API-682 seal chamber.

• Modular design and high pressure design available.

MAIN BENEFITS

• Low vibration assure smooth operation over a wide flow range.

• Wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

• Ample amterials selection in accordance with ISO-13709 / API-610.

• Low maintenance costs.

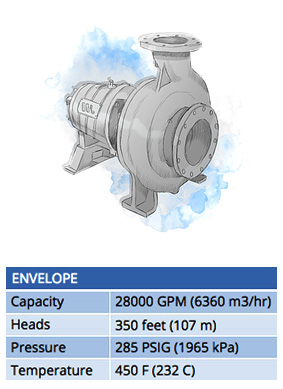

APP SERIES

Heavy duty paper stock and process overhung slurry and solids handling pump Series. Is one of the world's most efficient and reliable pumps. Able to perform effectively across a broad operating range, the high efficiency of the APP translates into low total cost of ownership.

MAIN APPLICATIONS

• Bleach Chemicals.

• Chemicals and Liquors.

• Coatings.

• Digester.

• Oil sand and shale.

• Paper stock.

• Sewage collection and treatment.

• Slurry transfer and processing.

MAIN FEATURES

• Self-venting, top centerline discharge casing.

• Semi-open, full vane impeller with back pump-out vanes.

• Large suction inlet.

• Stuffing box versatility.

• Back-pull-out design.

• Modular interchangeability.

MAIN BENEFITS

• Facilitates inflow of stock.

• Minimizes clogging.

• Prevents stock separation or dewatering.

• Low maintenance cost.

• Easy of service and maintenance.

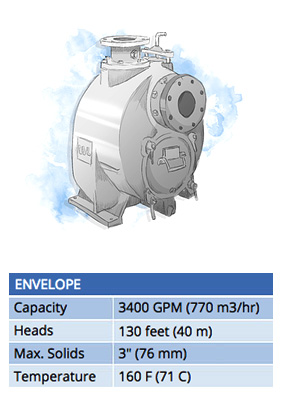

SPG SERIES

Inherently designed to allow the pump to reprime itself typically under lift conditions. These pumps are very effective to eliminate the need for foot valves, vacuum and injector pumps which can become clogged or be impractical to use for prolonged or remote operation.

MAIN APPLICATIONS

• Construction dewatering.

• Industrial applications.

• Municipal.

• Agricultural.

• Mining.

• Food processing.

• Paper mills.

• Oil & gas.

MAIN FEATURES

• External shimless impeller adjustment.

• Replacable wear plates.

• Removable rotating assembly.

• Bearing oil monitor.

• Atmospheric bearing isolation.

• Solids handling non-clogging open impeller.

• Removable coverplate.

• Wear resistance heavy-duty castings.

• Wide range of optional accessories.

MAIN BENEFITS

• Fast and easy service and maintenance.

• Clogging kept to a minimum.

• Downtime virtually eliminated.

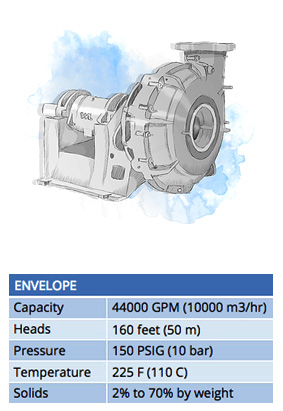

AH SERIES

The pump's hydraulic design, materials of construction and configuration versatility provide the necessary durability required to handle the harshest applications in mining, mineral processing, metal production and pollution abatement.

With its corrosion and abrasion resistant high chrome iron casing Series pumps and the rubber-lined ones; together, they form an extended product range. This versatility allows pumps to be well configured to site requirements and sized to their best possible performance.

MAIN APPLICATIONS

• Mining and mineral processing.

• Primary metals processing.

• Sand and gravel.

• Flue gas wet scrubbing.

• Synthetic fuels.

• Ethanol production.

• Oil sand and froth processing.

MAIN FEATURES

• Numerous shaft sealing options.

• High pressure modifications.

• Interchangeability among designs.

• Severe duty compact design.

• Hard metal casing and wear plates.

• Closed impeller design reduces stuffing box pressure and suction recirculation while sweeping away solids.

MAIN BENEFITS

• Handles high concentrations of coarse, abrasive solids in suspension.

• Reduced operating costs via optimal hydraulic selection.

• Easy of maintenance and operation.

• Generously sized to handle belt drive loads and can be removed easily in one piece for maintenance.

• Impeller end-clearance restorage to optimize efficiency without using shims.

• Easy access to stuffing box for service.

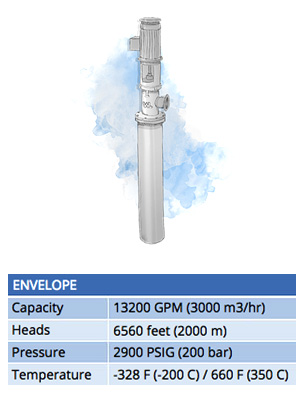

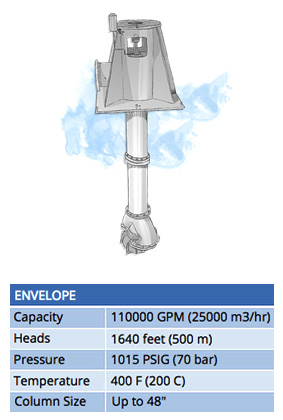

VTC SERIES

These Series of pumps are available in a wide variety of configurations, constructions and materials as needed. Designed for continuos duty applications and is particularly well suited for services with limited NPSH.

MAIN APPLICATIONS

• Pipeline booster.

• UNloading and transfer.

• Refinery blending.

• Injection-secondary recovery.

• Boiler feed.

• Condensate.

• LNG transfer.

MAIN FEATURES

• Fabricated discharge head.

• Flanged bowl construction.

• Suction in barrel as alternative.

• Suction bell designed to provide efficient flow into the eye of the first stage impeller.

MAIN BENEFITS

• In-line suction and discharge simplifies installation.

• Inherent efficient operation at any NPSH available.

• Modular design offers different configurations according to the application requirements.

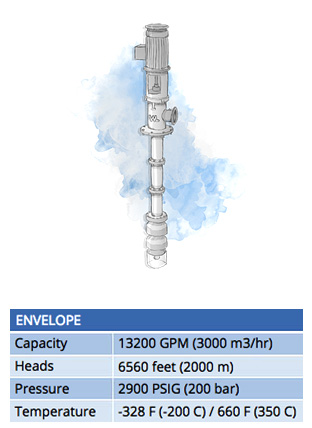

VTP SERIES

These Vetical Turbine Pumps has been specified for difficult or unusual applications, such as limited floor space, reduced operating noise levels, high efficiency, high discharge pressures and unusual suction conditions as required for low NPSH.

Designed primarily for heavy duty, continuous operation, in municipal and industrial applications.

MAIN APPLICATIONS

• Waste water.

• Municipal water supply.

• Booster systems.

• Hydrocarbon transfer.

• Mine dewatering.

• Offshore platforms.

• Cooling towers.

MAIN FEATURES

• Standard cast iron discharge head. Optional fabricated steel construction or underground discharge are available.

• Balanced enclosed type impellers.

• Cast bowls with integral vanes to guide the flow to the next stage.

• Bypass ports cast in the top bowl equalize internal pressure and prevent the pumped liquid entering the lubrication line and bearings.

• Threaded or flanged columns available.

MAIN BENEFITS

• Minimum losses and maximum efficiency.

• Standarized options and multiple materials and sealing configurations.

• Low noise and bivration levels and smooth operation.

• Robust and reliable long trouble-free life design.

VTP SERIESThese Vetical Turbine Pumps has been specified for difficult or unusual applications, such as limited floor space, reduced operating noise levels, high efficiency, high discharge pressures and unusual suction conditions as required for low NPSH.Designed primarily for heavy duty, continuous operation, in municipal and industrial applications. MAIN APPLICATIONS• Waste water.• Municipal water supply.• Booster systems.• Hydrocarbon transfer.• Mine dewatering.• Offshore platforms.• Cooling towers. MAIN FEATURES• Standard cast iron discharge head. Optional fabricated steel construction or underground discharge are available.• Balanced enclosed type impellers.• Cast bowls with integral vanes to guide the flow to the next stage.• Bypass ports cast in the top bowl equalize internal pressure and prevent the pumped liquid entering the lubrication line and bearings.• Threaded or flanged columns available. MAIN BENEFITS• Minimum losses and maximum efficiency.• Standarized options and multiple materials and sealing configurations.• Low noise and bivration levels and smooth operation.• Robust and reliable long trouble-free life design.

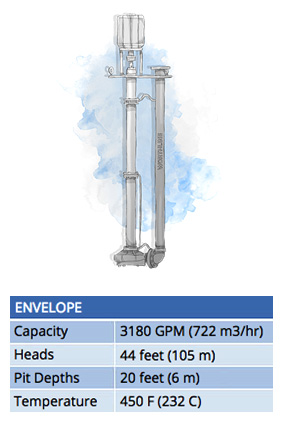

QL SERIESVertical, double suction pump has a single impeller and true twin volute design that produces more head and can operate at higher speeds than conventional, multistaged vertical turbine models. It can be used in all wet pit applications and virtually eliminates erosion and corrosion of the shaft, bearings and all internal components. MAIN APPLICATIONS• Cooling towers.• Water supply and distribution.• Sewage collection and treatment.• Dewatering and flood control.• Irrigation. MAIN FEATURES• Double Suction Impeller features large passageways producing balanced hydraulic thrust.• Heavy walled, twin volute casing with robust transition diffuser.• Suction bell efficiently direct liquid into the impeller inlets with minimum resistance.• Bottom liquid-end bearing is sealed for life with grease.• Heavy duty discharge head. MAIN BENEFITS• Stable performance curve with low shut-off pressure.• Low liquid velocity, minimize corrosion, erosion and radial loads on bearings.• Optional impeller wear rings enable restoration of original clearances for increased efficiency.• Reliable motor alignment providing liquid-end column support.

Es un líder mundial reconocido por su calidad, experiencia en bombas y componentes de alta ingeniería. La investigación continua hace que logren equipos con consumos de energía eficientes menores a comparación de otros productos en el mercado.

Sus líneas de grandes caudales incluyen:

• Bombas ANSI (compatibles con GOULDS y Worthington)

• Bombas Verticales y Horizontales

• Para Altas Viscocidades

Actualmente sus equipos están bien posicionados en sectores:

• Petroquímico

• Industria azucarera

• Acera

Servicios adicionales

Cuenta con el departamento de ingeniería inversa, en dónde se puden fabricar equipos y refacciones que ya no se fabrican por disncontinuidad o alto grado de complejidad.