WLPUMPS el primer distribuidor de Finish Thompson® en México

Bombas ANSI sin sello mecánico

Bombas neumáticas doble diafragma

Bombas para vaciado de tambores

Bombas plásticas acople magnético sin sello mecánico

Estamos remodelando nuestra página para ti

FTI's DB Series Magnetic Drive Pumps are the product of advanced engineeringCFD design software and superior magnetic flux technology. Using powerful neodymium magnetic technology, the DB sealless mag drive pumps are an ideal replacement for mechanical sealed pumps in corrosive duty applications. Premium features

Include:

• Highest efficiency - Up to 70% efficiency lowers cost of ownership by significant savings of electricity. Can save thousands of kWh per year on your electric bill.

• Best run dry ability - Superior run dry ability helps protect the pump from system upset or operator error. Eliminates costly repairs and downtime.

• Best warranty - Careful attention to detail results in a mag drive pump that is the most reliable and efficient on the market, offering five years of peace of mind.

• Best corrosion resistance - Durably molded from corrosion resistant polypropylene or PVDF, the DB Series handles the most corrosive chemicals with ease. Prevents downtime due to pump corrosion problems.

• High working pressure - Allows high specific gravity fluids to be safely pumped. Protects against unexpected surges in system pressure.

• Multiple connections - NPT or BSP threads, adjustable flanges or union connections make it easy to connect to any system reducing installation cost and time

• Standard NEMA or IEC motors - DB Series mounts to all standard motors.

• ATEX certified models available.

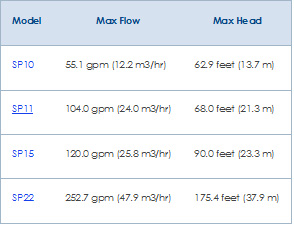

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Sealless, Self-Priming, Plastic, Horizontal

FTI's SP Series Magnetic Drive Self-Priming Pumps are the product of advanced engineering CFD design software and superior magnetic flux technology. The SP Series combines deep-lift capabilities and lightning-fast priming with the advantages of neodymium magnetic drive technology and corrosion resistant polypropylene and PVDF to handle the most difficult applications with no seal replacement, no leaks and the capability to run-dry without damage.

• Powerful - The SP's careful engineering resulted in a unique design that allows it to create a powerful, deep vacuum in the suction piping. This allows it to lift fluid from as deep as 25 feet (7.6 m) below the pump. Superior lift and high working pressure capabilities allow SP Series to pump high specific gravity fluids like sulfuric acid, phosphoric acid and sodium and potassium hydroxide with ease.

• Fast - SP Series is capable of lifting fluids from 18 feet (5.5 m) in less than 90 seconds. Less time waiting, more time pumping.

• Versatile - The priming ability of the SP Series allows the pumps to handle applications difficult for standard centrifugal pumps. Such applications include pumping fluid from below grade, emptying tanker trucks or rail cars, and transferring fluids from the top of tall bulk storage tanks to reduce the possibility of leaks from sidewall mounted bulkhead fittings.

• Economical - SP Series are extremely efficient in their use of energy. They offer tremendous savings compared to self-priming AOD (air operated double diaphragm) pumps. SP Series use only a fraction of the energy AODpumps require.

• Run dry ability - Run dry ability helps protect the pump from system upset or operator error. Eliminates costly repairs and downtime.

• Best warranty - Careful attention to detail results in a mag drive pump that is the most reliable and efficient on the market, offering five years of peace of mind.

• Best corrosion resistance - Durably molded from corrosion resistant polypropylene or PVDF, the SP Series handles the most corrosive chemicals with ease. Prevents downtime due to pump corrosion problems.

• Multiple connections - NPT or BSP threads, adjustable flanges or union connections make it easy to connect to any system reducing installation cost and time

• Standard NEMA or IEC motors - SP Series mounts to all standard motors.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Sealless, Plastic, Horizontal

Next generation mag drive pumps, the DB Series, are now available.

View the DB Series pumps.

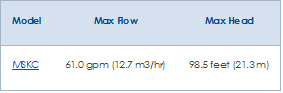

Multi-Stage, Sealless, Plastic, Horizontal

Manufactured from corrosion resistant polypropylene or PVDF, MSKC Series horizontal centrifugal pumps are designed to provide years of reliable service.MSKC Series pumps feature state of the art magnetic coupling technology that results in a leak-proof design. Multiple impellers allow for a small footprint with smaller motors. These pumps offer excellent corrosion resistance and are available in a various impeller combinations. MSKC Series pumps feature outstanding run dry ability when equipped with a carbon bushing.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Vertical, Sealless, Plastic

Vertical, magnetic drive centrifugal pumps (VKC) in polypropylene or PVDFmaterials are designed to provide years of reliable service.

VKC Series pumps feature state of the art magnetic coupling technology, which allows for a completely sealed column that prevents aeration, micro-bubbles and the release of fugitive emissions.

These pumps offer excellent corrosion resistance and are available in a wide range of sizes.

Multi-Stage, Vertical, Plastic

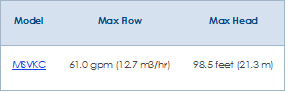

Manufactured from corrosion resistant polypropylene or PVDF, MSVKC Series vertical centrifugal pumps are designed to provide years of reliable service.MSVKC Series pumps feature state of the art magnetic coupling technology that allows for a completely sealed column, which prevents aeration, micro-bubbles and the release of fugitive emissions.

Multiple impellers enable a small footprint with smaller motors. These pumps offer excellent corrosion resistance and are available in a various impeller combinations.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Chemical Process, Corrosion Resistant Pumps

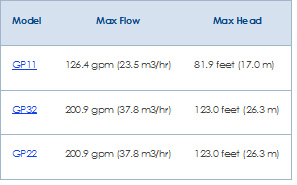

GP Series centrifugal pumps are designed to provide years of reliable service in chemical transfer applications. These value priced industrial pumps offer excellent corrosion resistance and are available with a wide range of mechanical seals. They can accept NEMA or IEC motors. GP11 and GP22 models feature threaded connections; GP32 features flanged connections.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Stainless Steel Centrifugal Pumps, Horizontal

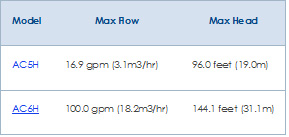

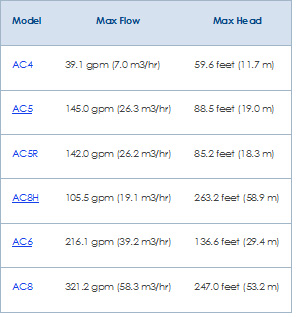

Stainless steel (316) centrifugal pumps are designed to provide years of reliable service. A wide variety of port sizes, impeller diameters and seal options make AC Series horizontal centrifugal pumps extremely versatile.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Stainless Steel, Cantilevered Vertical, Sealless

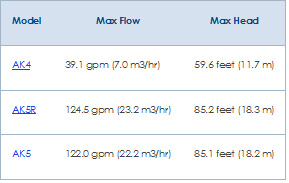

Manufactured from rugged, corrosion resistant 316 stainless steel, AK Series vertical centrifugal pumps are designed to provide years of reliable service. AK models feature 12” (30 cm) long cantilevered designs.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Stainless Steel, Sealless, Vertical

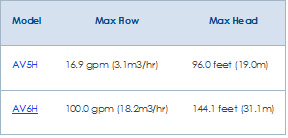

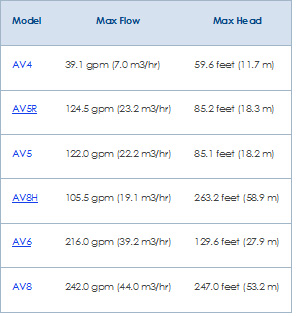

Manufactured from rugged, corrosion resistant 316 stainless steel, AV Series vertical centrifugal pumps are designed to provide years of reliable service. A wide variety of port sizes, impeller diameters and column lengths make AV Series pumps extremely versatile.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

ETFE Lined, Sealless ANSI Dimensional

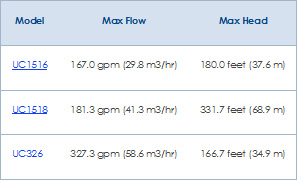

Rugged, durable UC Series pumps provide excellent corrosion resistance. Features include heavy duty ductile iron casings lined with pure Tefzel® (ETFE), modified concentric volutes to reduce radial loads, rear sealing ring and balance holes to reduce axial loads and premium silicon carbide components. Magnetic drive UC Series pumps are engineered for long life in the most demanding applications. Atex certified models are available.

The pump models below have multiple impeller diameters which allow for enhanced hydraulic selection and application flexibility. Simply click on the model to view specific performance for each impeller diameter.

Best Value - Medium Duty

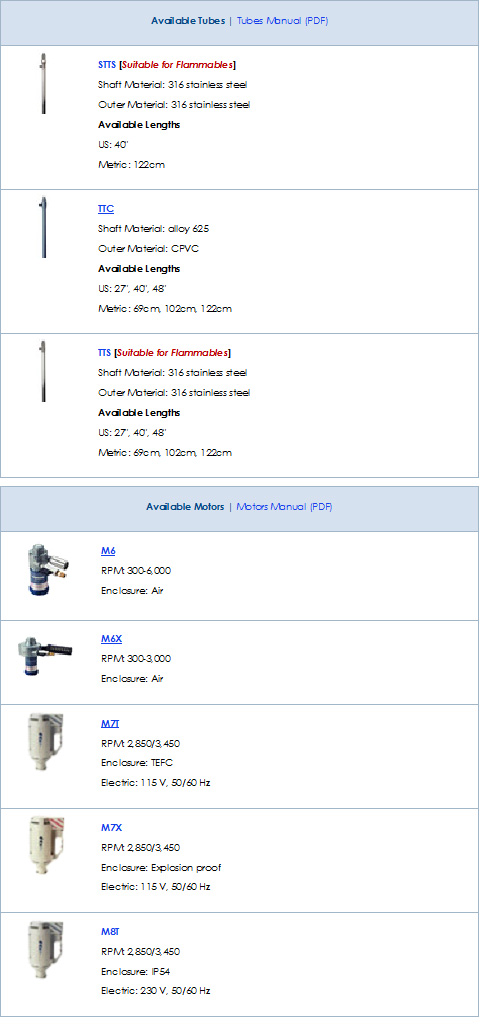

The EF Series drum (container) pump is an ideal combination of performance and value. The patented sealless design and carefully chosen, corrosion resistant materials of construction assure a long, trouble-free life. It is lightweight and easy to use yet amazingly powerful. The EF Series is available with multiple tube materials and motors to handle a wide variety of applications including the transfer of diesel exhaust fluid. The tubes are available in various lengths for a variety of container types from pails and drums to totes (IBC's) and small tanks.

Features

• Application examples include: light acids and bases, bleach, cleaners, plating solutions, Diesel Exhaust Fluid (DEF/AdBlue)

• Up to 1.2 SG

• Up to 300 cP

• Polypropylene tube with 316 SS shaft, pure polypropylene/PVDF tube with Alloy 625 shaft, or 316 stainless steel tube with 316 SS shaft

• 16" (41 cm), 27" (69 cm), 40" (102 cm), 48" (122 cm) tube length to handle various container types

• Two-speed splashproof electric or air motor options

• Unique integrated hose and cord clip

• Corrosion resistant, industrial duty pump

Pat. US D658,273 S; Pat. US D657,849 S; Pat. ZL 201130042121.X; Pat. ZL 201130042107.X; OHIM Pat. 001839002-0002; OHIM Pat.001839002-0001

S6 Series Brochure

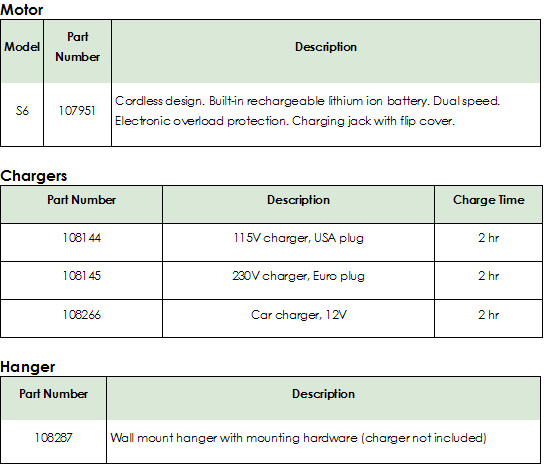

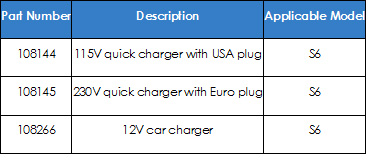

The S6 is a low cost, lightweight, cordless drum pump motor that works with all EF Series pump models. With a 12-volt lithium ion battery, the S6 can run up to 50 minutes before requiring a charge. And charging is fast with our 2-hour quick chargers.

This powerful motor can handle fluids with specific gravities up to 1.6 and viscosities up to 100 cP, yet weighs only 3 lbs. The cordless design makes for stress free pumping off-site, on deliveries, or in areas with limited or no electricity. Versatile dual speed control allows greater flow control. Dual cooling fans and overload protection help maintain battery life of the S6.

Three charger options are available as well as a wall hanger accessory for motor, pump and charger.

Features

• 12V (10.8V under workload), 3,200 mAh lithium ion battery

• Cordless design for ultimate portability

• Lightweight yet powerful

• Dual speed for precise fluid dispensing

• Dual cooling fans for longer battery life

• Electronic overload protection

• Integrated charging port

• Fits all EF Series pump tubes

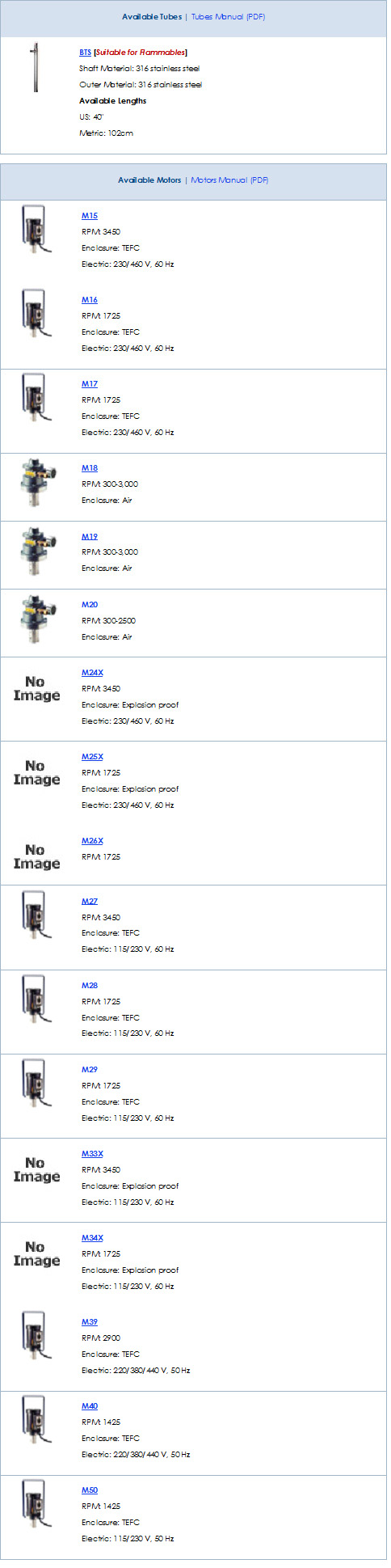

Most Versatile - High Flow

The PF Series are high performance, sealless drum/barrel pumps designed for container-to-container transfer of acids, corrosives, and chemicals. It is excellent for DEF or diesel exhaust fluid transfer (PFM Series).

Features

• Polypropylene, PVDF or 316SS tubes (PFM/PFP patented)

• Splashproof, TEFC, Explosion proof or Air motors

• Unique double suction impeller

• Variable flow orifice (PFP & PFV only)

• Pump tubes interchangeable with motor selections

• Easy disassembly for cleaning

When pumping flammables or combustibles, use explosion proof electric or air motors on stainless steel tubes with a Static Protection Kit.

ATEX certified models are available in the PFS Series tubes.

Pat. US D658,273 S; Pat. US D657,849 S; Pat. ZL 201130042124.3; Pat. ZL 201130042107.X; OHIM Pat. 001839002-0003

Light to Medium Viscosity - Medium Flow

The lightweight TB Series drum (container) pump is suitable for mild corrosives and solvents. Its 1 ½" tube width fits containers with smaller bung openings.

Features

• Sealed

• Unique lifting compressor design

• Handles mild corrosives and solvents

• Pump tubes interchangeable with motor selections

• Stainless steel construction

When pumping flammables or combustibles, use explosion proof electric or air motors on stainless steel tubes with a Static Protection Kit.

ATEX certified models are available in the PFS Series tubes.

Light to Medium Viscosity - Medium Flow

The economical TBP series drum (container) pump handles light to medium viscosity fluids. Constructed of pure materials, it is ideal for use with bleach, nitric acids, hydrochloric acids, sulfuric acids, etc. The 1.66" (42mm) tube diameter is designed to accommodate drums with smaller bung openings. Typical applications include: Municipal water treatment facilities, swimming pool supply houses, water parks, anywhere that bleach is used in drums/barrels or containers.

Features

• Sealed

• Unique lifting compressor design

• Handles corrosive liquids

• Pump tubes interchangeable with motor selections

Do not use TBP Series pumps for flammables or combustibles.

Medium Viscosity - Medium Flow

The TT series pumps are ideal for corrosive chemicals or solvents, flammables, and applications requiring high purity or sanitary construction. Typical uses include detergents, vinegar, motor oils, and semi viscous liquids.

Features

• Sealed

• Handles mild corrosives, solvents and flammables

• Tube interchangeable with motors

• CPVC, stainless steel or USDA sanitary constructions (STTS model)

• Unique lifting compressor desig

When pumping flammables or combustibles, use explosion proof electric or air motors on stainless steel tubes with a Static Protection Kit

ATEX certified models are available in the PFS Series tubes.

High Viscosity - High Head

The BT series is for high viscosity mild corrosives and flammables. Use for pumping polymers, adhesives, oils, resins, etc.

Features

• Sealed

• Tube interchangeable with motors

• Unique lifting compressor design

• Stainless Steel and PTFE construction

When pumping flammables or combustibles, use explosion proof electric or air motors on stainless steel tubes with a Static Protection Kit

High Viscosity - High Head

HVDP Series drum pumps are positive displacement pumps using a progressive cavity design to gently move highly viscous materials up the pump tube in a smooth, non-pulsing flow. The progressive cavity design requires a relatively slow speed to operate properly. A planetary gear set speed reducer enables the HVDPSeries pumps to accept 800 watt universal, induction or air motors.

Features

• Progressive cavity design

• Up to 100,000 cP

• 316 stainless steel tube and shaft

• Buna-N, Viton®, or PTFE stator materials

• Mechanical seal

• Unique camlock feature easily disengages tube for cleaning

• HR versions for use with M58H or M59H universal motors

• LR version for use with air or induction motors (M60-M66)

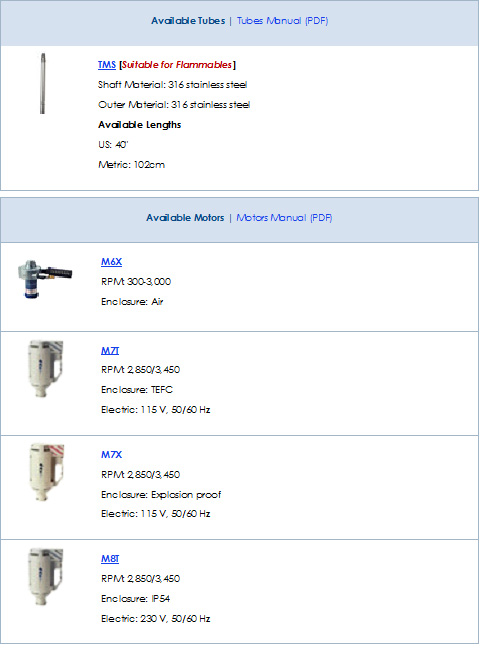

Medium Viscosity

The TM Series Drum Mixer is a 4-blade, turbine drum mixer ideal for mild corrosives, solvents, or flammables of light to medium viscosity.

Features

• Sealed

• Turbine mixing and blending

• Non-aerating, non-vortexing circulation

• Loosens and suspends bottom sediments

• Handles corrosive materials

• Pump tubes interchangeable with motor selections

When pumping flammables or combustibles, use explosion proof electric or air motors on stainless steel tubes with a Static Protection Kit.

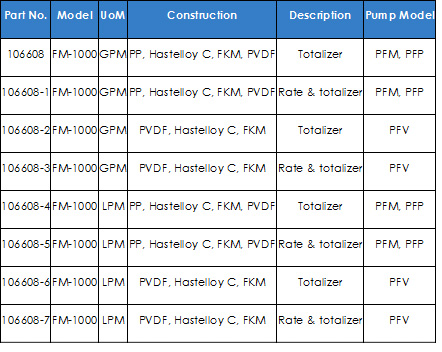

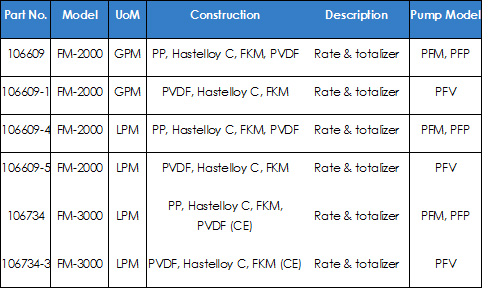

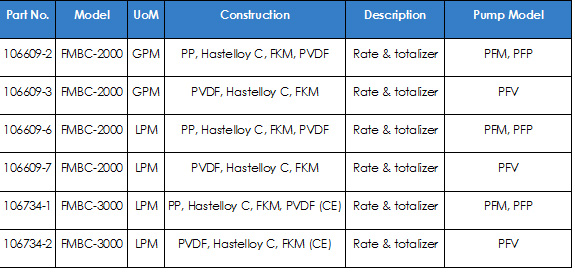

Designed to work with PF Series pump tubes, FTI’s line of flow meters allow customer’s to dispense precise volumes of fluids from drums, barrel, totes and other containers.

How do FTI flow meters work?

As liquid flows through the body of the flow meter, it rotates a paddlewheel sensor that has small magnets encapsulated in corrosion resistant plastic. As the paddlewheel rotates, the magnets pass by sensors creating a signal. A microprocessor converts these signals into flow and the results are shown on the liquid crystal display.

Available in corrosion resistant polypropylene or PVDF, FTI flow meters are designed to handle a wide variety of fluids including aggressive materials like acids and bases.

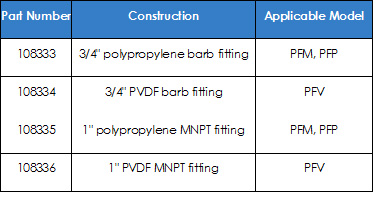

Engineered connection components are included with each meter to allow fast assembly to PFM, PFP and PFV drum pump tubes.

Factory calibrated to high +/- 1% accuracy and repeatability, some versions also allow the meter to be user calibrated for custom flow rates and fluid characteristics.

A variety of meters are available including batch control versions that stop the pump after a customer adjustable, preset volume is pumped.

Available models include FM1000, FM2000 and FM3000 series.

Centrifugal Pump Accessories

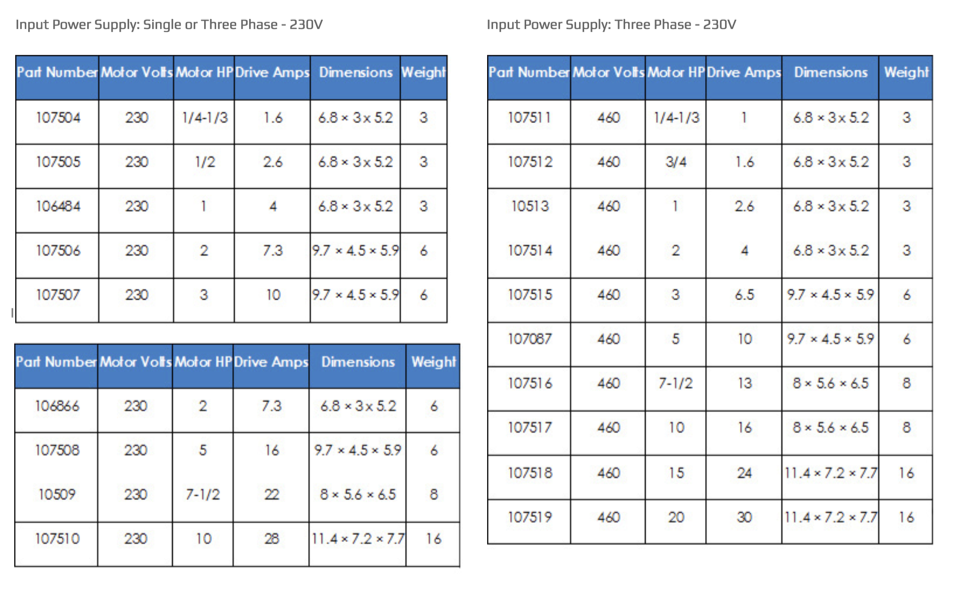

Variable Frequency Drive

Variable frequency drives from Finish Thompson are easy to install and operate, offering innovative technology in a compact size. Simply select a VFD from the available models below based input power and motor voltage. Contact Finish Thompson for additional assistance.

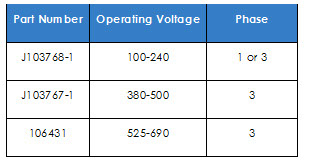

Finish Thompson's deluxe M20 Power Monitor with digital display and PLC output provides outstanding protection against pump failure due to run dry, dead heading, excess power, de-coupling and lack of priming (SP Series).

The M20 operates at 50 or 60 Hz, is easy to install, and offers four levels of protection (pre-alarm minimum & maximum power; alarm minimum & maximum power). Just three models cover all motor voltages up to 690 VAC and a transducer is included with each M20 at no additional charge.

For selection assistance, please contact Finish Thompson. Please have the voltage the motor will operate at and, if not ordering a motor with the pump, please also provide the motor data (i.e. brand, single or 3-phase, HP, etc.).

Power Monitor Flyer

M20 Power Monitor Options

Available Transducers

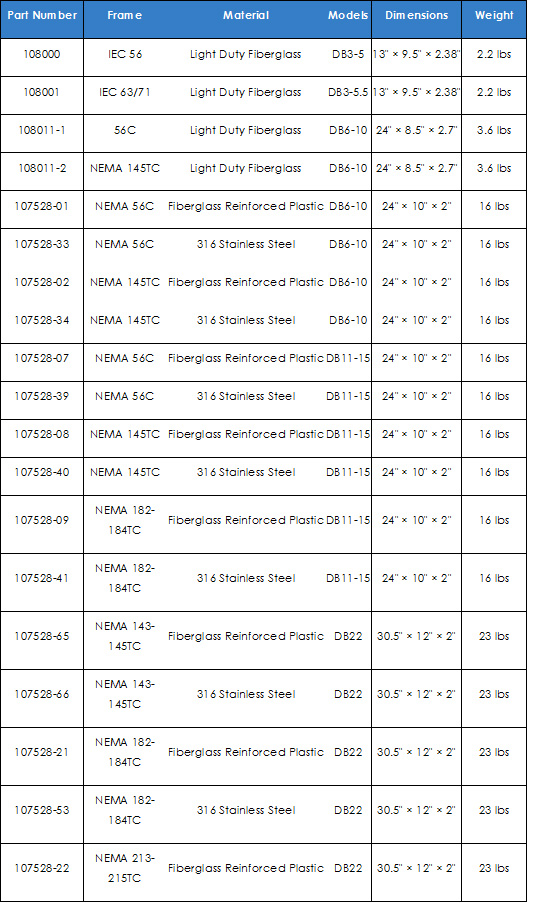

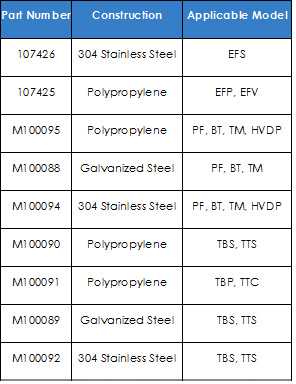

Finish Thompson offers corrosion resistant base plates for use with our DB, SP,and UC Series pump models. Base plates lift the pump and motor off the floor, preventing damage from floods or spills and allowing for safe clean up.

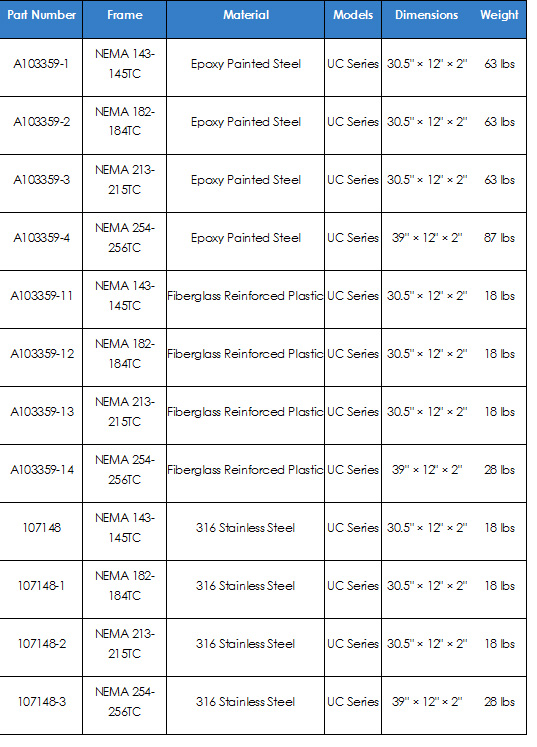

Available in FRP (fiberglass reinforced plastic), light duty fiberglass (for smaller models), 316 stainless steel, and epoxy painted steel (UC Series only), base plates are pre-machined to precisely fit Finish Thompson pumps and motors. Custom sizes and materials are also available upon request.

Stainless steel shims and hardware are included. Pump, motor and base plate will be assembled prior to shipping.

SP Series Close Coupled Base Plates

UC Series Close Coupled Base Plates

Pedestal assemblies enable a pump to be coupled to special AC or DC electric motors, air motors, gas or diesel engines, and hydraulic motors using a flexible coupling. Finish Thompson offers standard pedestal assemblies to fit any of our horizontal centrifugal pumps with a NEMA 56C motor adapter.

A pedestal assembly option is also offered for the UC Series to fit NEMA frame sizes 145TC up to 256TC and IEC 90 up to 160.

Optional pedestal frame accessories, such as couplings, coupling guards, and base plates are available upon request.

Finish Thompson flow meters can dispense and batch precise amounts of fluids from drums, barrels, totes and other containers. Constructed of splash- and corrosion-resistant polypropylene or PVDF construction, flow meters can handle a wide variety of chemicals and corrosive liquids such as acids, bases, cleaners, coolants, plating solutions, pesticides and herbicides.

They are available as standard preset factory calibrated to provide flow rate and total volume pumped, with user calibration available for custom flow rates and totals available in select models. Batch control, available on FMBC models, stops the pump after a customer adjustable preset volume has been pumped.

With an easy to read LCD display, push-button interface, engineered connection components for fast assembly, and an automatic power down feature to extend the life of battery-operated models, FTI flow meters offer user friendly features for ease of pumping and dispensing.

Flow meters offers +/- 1% accuracy and repeatability when pumping fluids with viscosities up to 20 cP at temperatures ranging from 32˚ F (0˚ C) to 120˚ F (49˚ C) with flow ranging between 5 gpm (20 lpm) to 32 gpm (120 lpm). Meters are designed for use on PFM, PFP and PFV drum pumps. Please contact Finish Thompson for capabilities of specific models to ensure correct selection for your application.

Preset Factory Calibrated

User Adjustable Calibration

User Adjustable Calibration with Batch Control

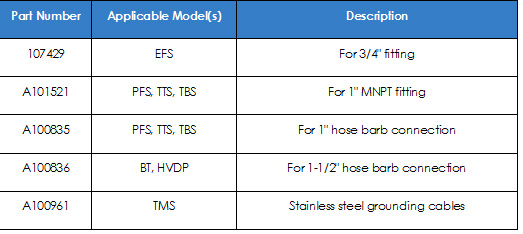

Finish Thompson’s Static Protection Kit (SPK) is recommended to help prevent the accumulation of static charge when transferring flammable or combustible liquids. It is to be used in conjunction with stainless steel drum pumps and air or explosion-proof electric motors.

When pumping flammables at high flow rates, a static charge can build up due to the high velocity at which the fluid is moving. Static charge can become a spark capable of igniting flammable liquids. This is rare occurrence, but it is wise to prevent the possibility by using the SPK. Keeping the velocity of the liquid low significantly reduces these hazards. Our metal tube pumps combined with an appropriate motor and static protection kit is an engineered package designed to provide customers with a high level of protection when pumping flammable liquids.

The SPK is a conductive, 4-foot long x 1-inch I.D. cross-linked polyethylene discharge hose with grounding cables to bond the pump, motor, hose and receiving drum. It will also limit the pumps output velocity to 3-feet/second maximum (about 7 gpm through a 1’’ hose), which will reduce the hazards of static build-up.

Custom hose lengths are available.

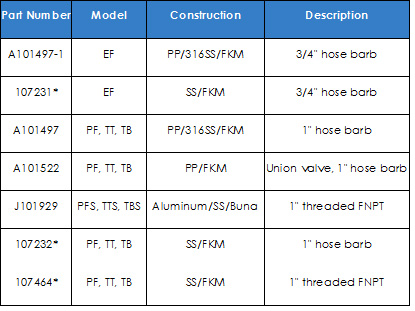

Nozzles allow for the safe dispensing of fluids and greater control when filling containers. Select from our available options below.

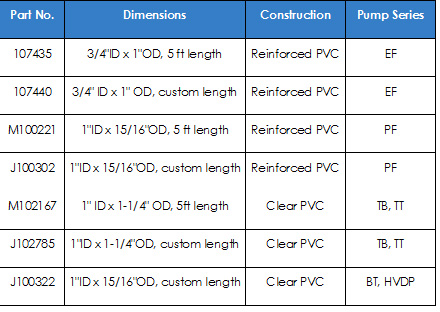

Flexible discharge tubing is used to safely transfer fluids from pump to container.

Discharge tubing is available in clear or reinforced PVC with operating temperatures ranging from -22˚ F (-30˚ C) to 175˚ F (79˚ C). Operating temperature is dependent upon material and applicable pump model.

Standard length is 5 ft., but tubing can also be purchased by the foot (4 ft. minimum is required).

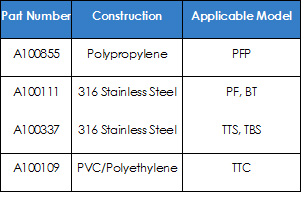

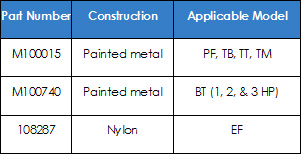

See Drum Pump Accessories Technical Flyer for additional information.

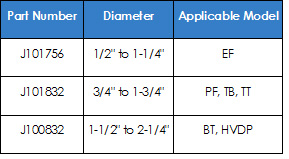

Stainless Steel Hose Clamp

Secures discharge tubing around pump and fittings.

Drum Adapter

Keeps pump snug in container bung & limits escape of fumes.

Fits standard 2" IPS bung opening.

Inlet Strainer

Prevents intake of objects or particulates.

Wall Mount Bracket

Stores pump upright on the wall.

Chargers

Charges S6 lithium ion motor in two hours.

Chargers

Charges S6 lithium ion motor in two hours.

USA manufactured, Finish Thompson Solvent Recycling systems incorporate superior technology and design to recycle almost any solvent for reuse. This solvent recycling (distillation) equipment has a proven track record. Thousands of satisfied customers use these solvent recyclers to successfully recycle millions of gallons of waste solvent on site each year.

Finish Thompson was a pioneer in the design and technology development of on site solvent distillation. FTI's batch distillation systems achieved patent status and received certification from independent testing agencies. Nearly 30 years of manufacturing experience in this industry earned FTI an international reputation as an expert in the design, manufacture, and application of solvent distillation/solvent recycling technology. FTI solvent recyclers carry a 3-year warranty along with a lifetime warranty on the heater unit.

BE Series

Finish Thompson's BE-55C antifreeze recycling system utilizes advanced vacuum distillation technology to recycle waste engine coolant.

Why use vacuum distillation to recycle waste engine coolant?

Simply put, FTI's patented distillation technology excels at removing all contaminants, both suspended and dissolved, from the waste coolant. It provides the highest quality, recycled coolant available and is the only process that removes water from the waste stream...resulting in a distillate (end product) of concentrated pure glycol.

This technology has been laboratory and fleet tested and is approved by numerous automotive and heavy duty OEMs. All recycling equipment is USAmanufactured following ISO9001 guidelines for consistency in manufacturing procedures and commitment to promised delivery schedules.

Numerous U.S. Government military installations around the world use the BE-55C to recycle waste engine coolant. This is an excellent testimonial to FTI's expertise in advanced recycling technology.